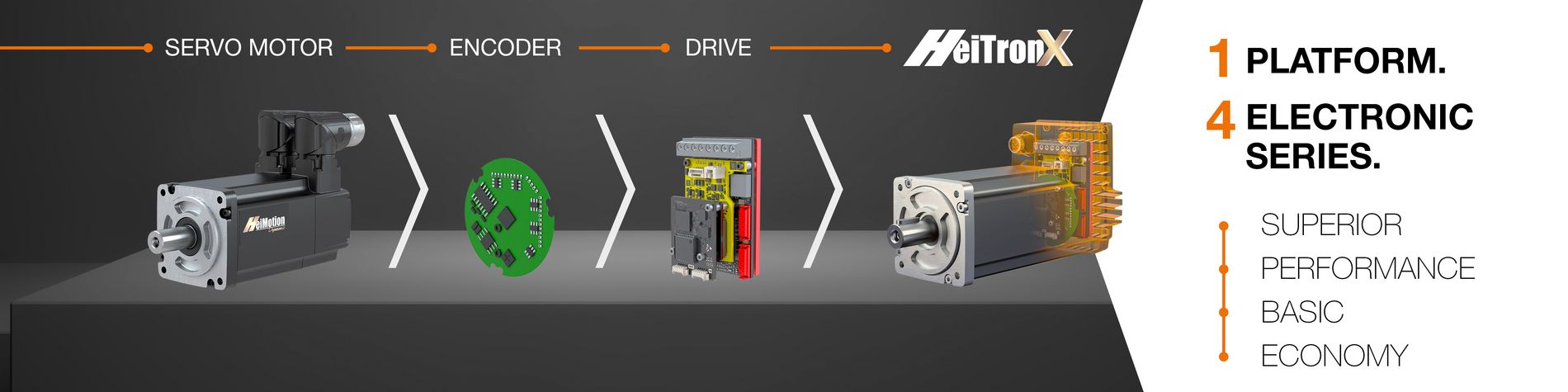

HeiTronX - 1 PLATFORM - 4 SERIES

Integrated and mounted servo motors

Small, intelligent and powerful is how integrated drives can be described in a few words. The fully digital servo positioning units are primarily intended for use in decentralized multi-axis applications where many motors are installed in one machine. These flexible space miracles are used primarily in robotics and automation and, thanks to their performance, are driving the success of the industry.

Within automation, the drive forms the heart of the system, as it brings the machine to life and represents the decisive interface. The fact that there must be differently configured drive types for different applications becomes clear at the latest when one takes a closer look at installation space, budget and the special customer requirements. For example, in an application the drive must be able to withstand strong vibrations or is exposed to high temperatures. In other applications, however, the requirement is to install as few cables and additional modules as possible due to the limited installation space. The latter is becoming increasingly important, particularly in automation and robotics. Decentralized drives are experiencing an upswing here and are finding their place in almost every application. However, if you take a closer look at the decentralized drives currently on the market, most electric motors are fitted with the controller system rather than integrated - the installation space that actually needs to be gained is minimized, since space is required, especially at height.

In the four series SUPERIOR- (HTS) PERFORMANCE- (HTP), BASIC- (HTB) and ECONOMY-Line (HTE), the encoders and electronics are placed directly in or on the motor profile, which allows space-saving installation even in compact applications. There is virtually no need for control cabinets and the amount of wiring is significantly reduced.

All four series are currently available in two resp. three sizes. While the ECONOMY-Line is currently available with flange sizes of 40 x 40 mm, 60 x 60 mm and 80 x 80 mm, the other three series HTS, HTP and HTB are available in flange sizes of 60 x 60 mm and 80 x 80 mm.

The decentralized drives are also impressive, among other things, for their high power and control capability. Another advantage of these drives is their low cogging torque with high energy efficiency and optimized temperature management.

The modern and extremely compact drive concepts can be integrated into a wide range of automation solutions and enable flexible applications. For example, the powerful and multifunctional motors can perform precise handling tasks in automation technology and robotics and are also used in manufacturing for the automotive industry.

For positioning, the electronics have been adapted to the new and in-house developed HES/HEM encoders (Heidrive Encoder Singleturn/Heidrive Encoder Multiturn). These require an accuracy of up to 12 bits despite the small installation space of only approx. 3 to 6 mm.

In order to dissipate the heat generated more quickly, an optimized thermal connection of the power output stage has been created. The cooling fins in the housing also ensure high heat dissipation, which can be increased in the HMDi06 from 200 W to 300 W continuous power by means of an optional fan. The protection class is IP54 as standard and can be increased to IP65 if required.

The HMDi06 electronics are also available in two different versions. The less expensive version, with a standard CAN driver and a common power supply for logic and power, has the basic functions. The premium variant offers the option of decoupling the supply of logic and power and is protected by an electrically isolated CAN driver.

The modern and compact drive concepts can be integrated into a wide range of automation solutions and enable flexible and cost-effective applications. For example, the powerful and multifunctional motors can perform precise handling tasks in automation technology and robotics. They are also used in manufacturing for the automotive industry, as the compact and cost-effective system offers many advantages for decentralized 24/48 V drives. Special integrated servo drives, also with direct gearbox mounting, are now also being used for ultra-fine metering equipment, where high dynamics are required with low conversion.

In addition, regardless of the special developments, it is possible to use the modular system of the company Heidrive. In this way, unlimited combinability with different sizes, planetary gearheads and connectors is possible.

The HeiMotion servo motors with attached electronics, on the other hand, are used especially for power-oriented applications.

The features at a glance:

- Highest synchronism and accuracy

- High efficiency

- Optimized moments of inertia

- Durable

- Compact design

- High power density

- Low cogging torque

- Energy efficiency

- Optimized temperature management